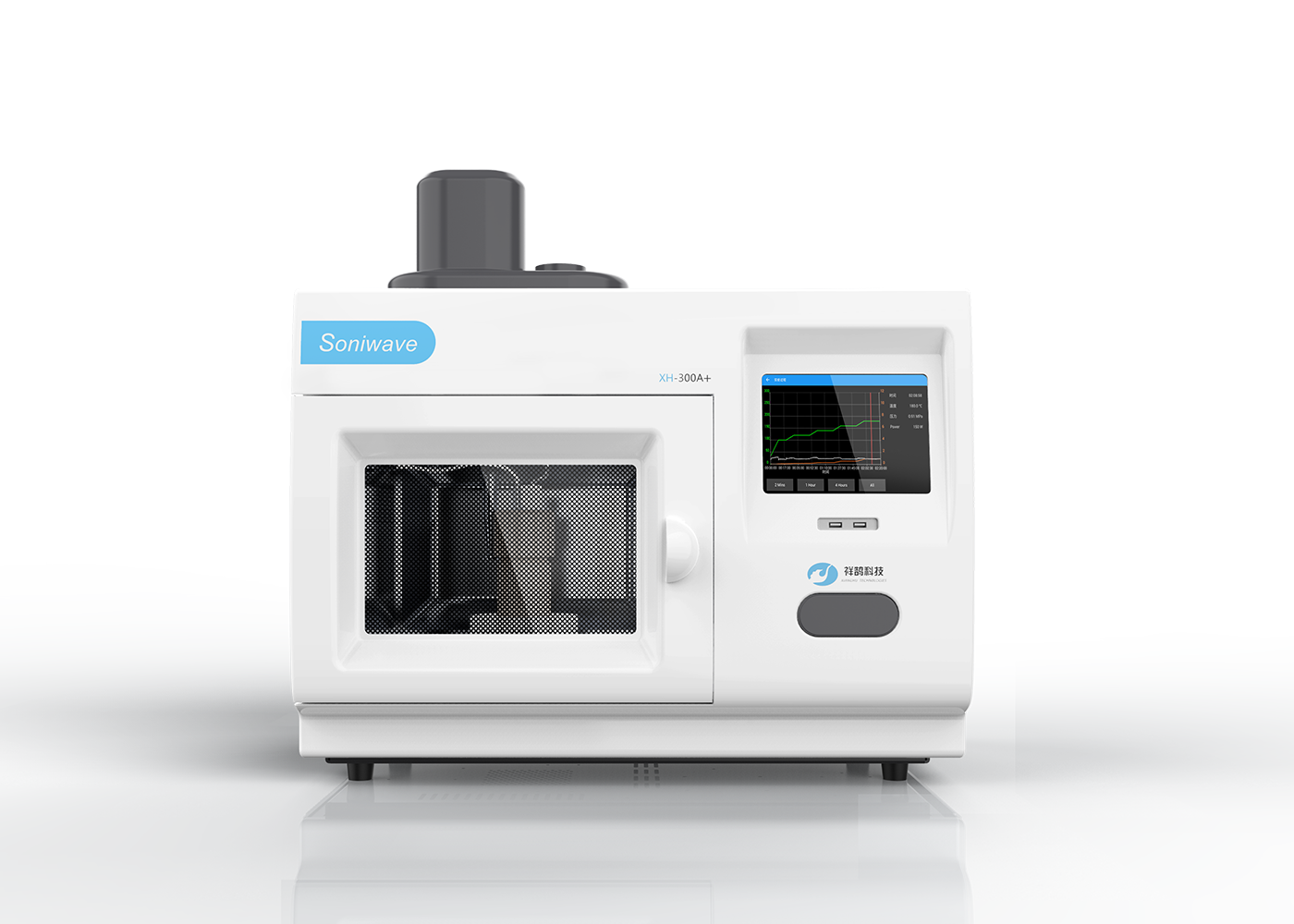

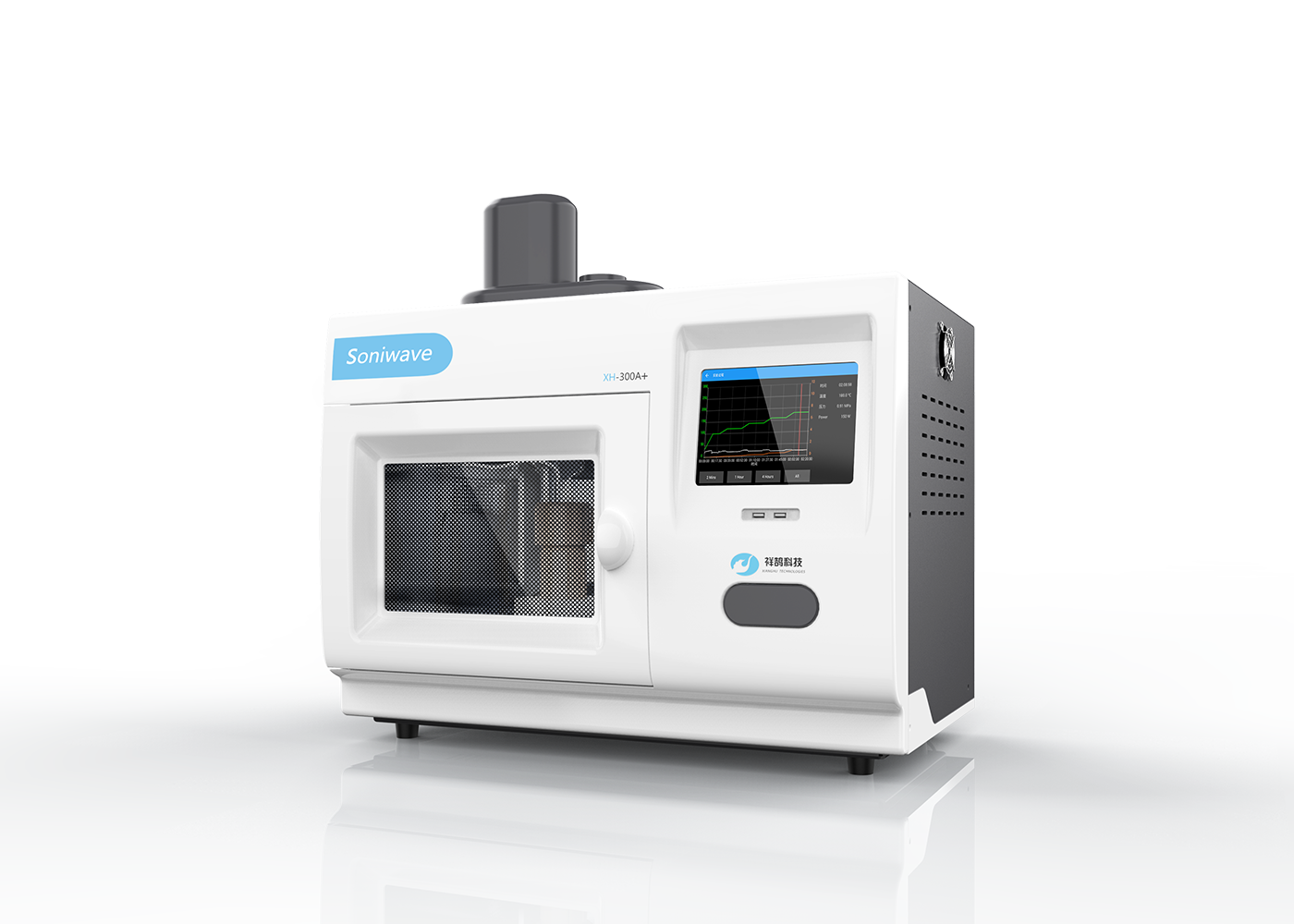

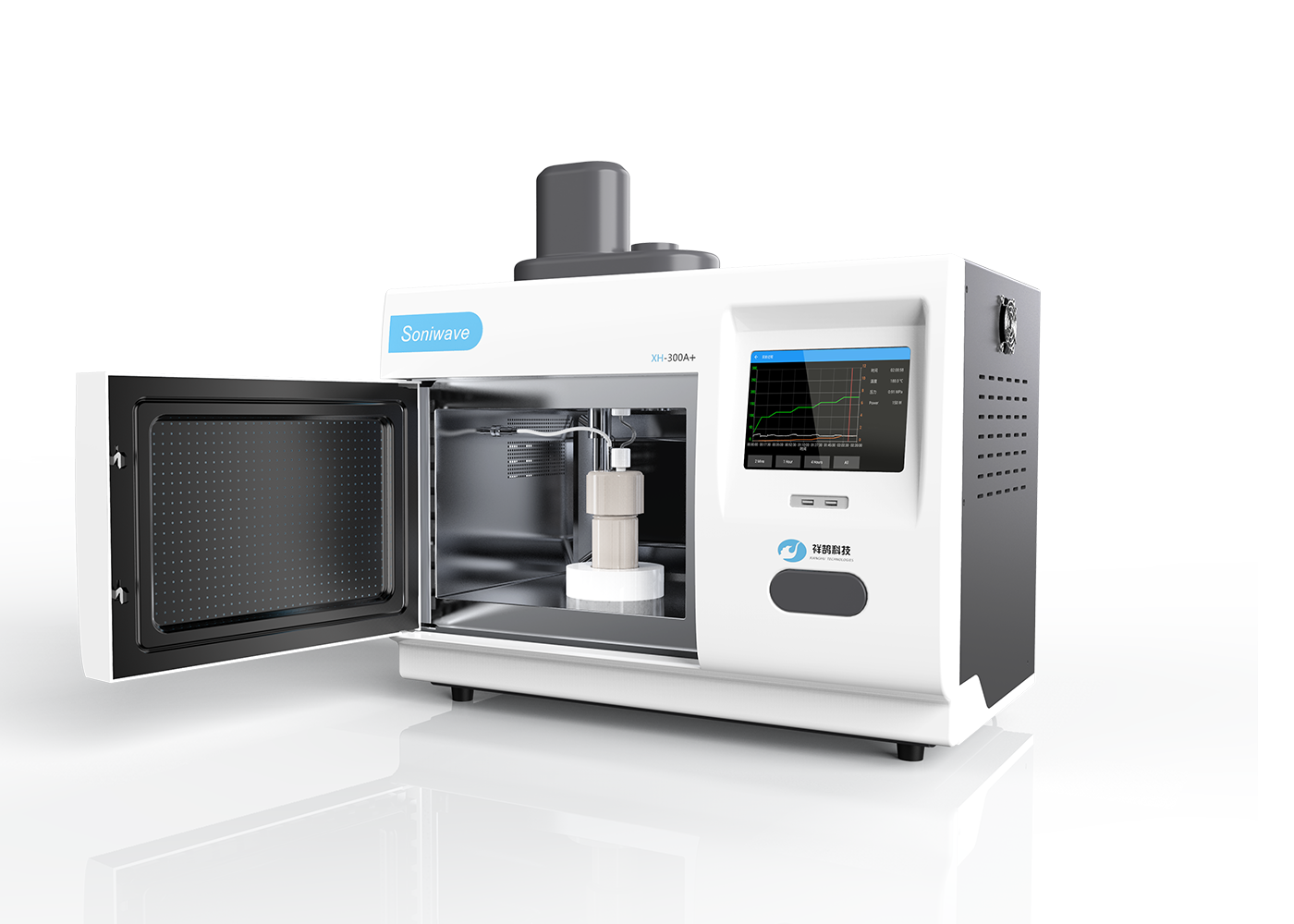

XH-300A+ Intelligent MW Ultrasonic Combined Synthetic Extractor

Soniwave

Instrument functions:

High Pressure Microwave|Atmospheric microwave|Energy Storage Conversion|Enyironmental waste deqradation |Material Preparation |Natural Products Extraction

Experimental function:

Ultrasound (scan)|Microwave|Microwave Ultrasonic Synergy

Experimental condition:

atmospheric|high temperature|liquid-phase (chemistry)

Experimental purpose:

Microwave Catalysis / Synthesis / Extraction|microwave hydrothermal|Ultrasonic extraction