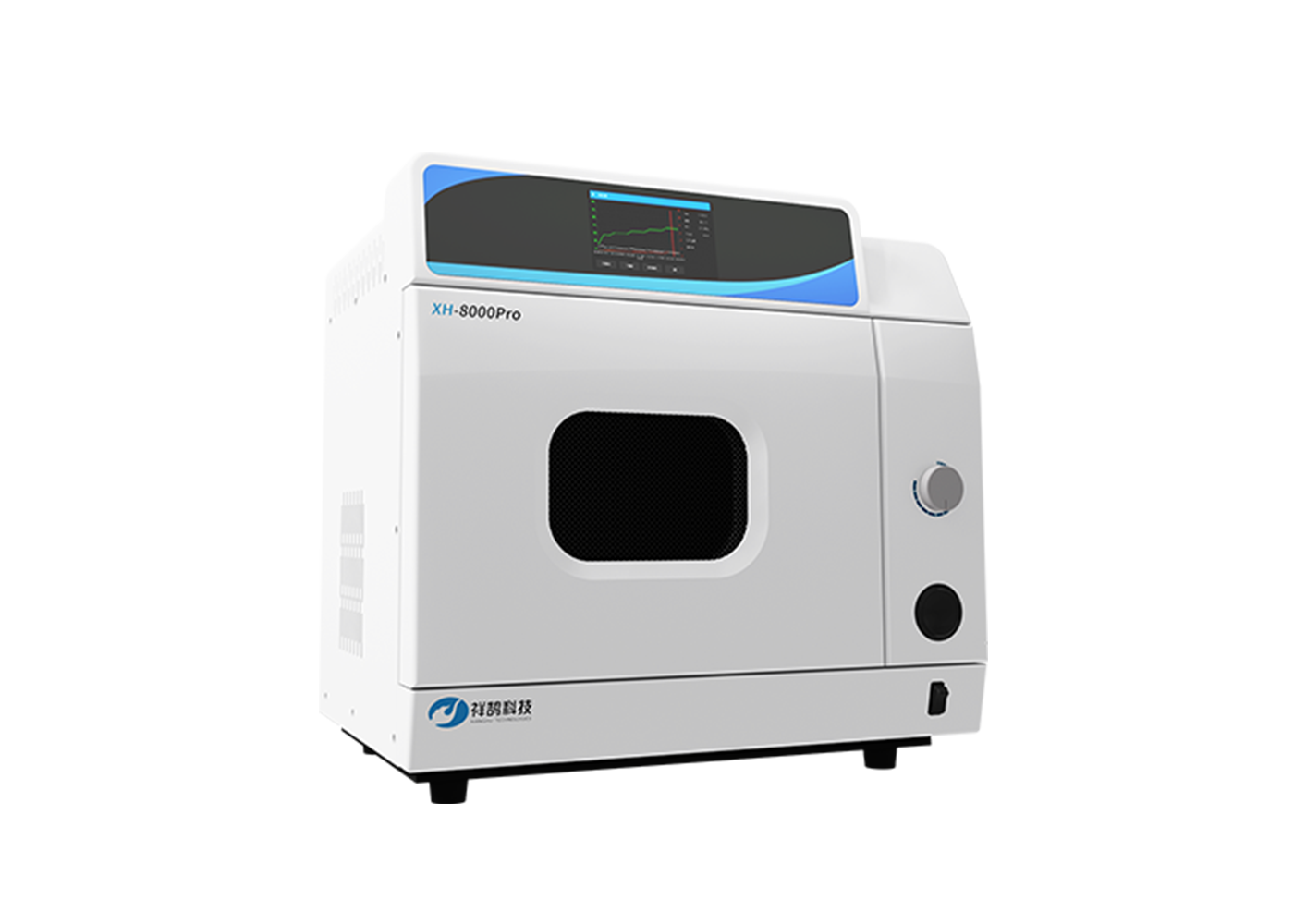

XH-8000Pro Multi-purpose MW synthesizer

Instrument functions:

Enyironmental waste deqradation |Organic/Drug Synthesis|Material Preparation |Natural Products Extraction

Experimental function:

Experimental condition:

Experimental purpose: