This paper, a researcher from the School of Materials and Chemical Engineering of Hainan University, discusses papers on the effects of different production processes on the ozone aging properties and structure of natural rubber. It is published in the important journal .

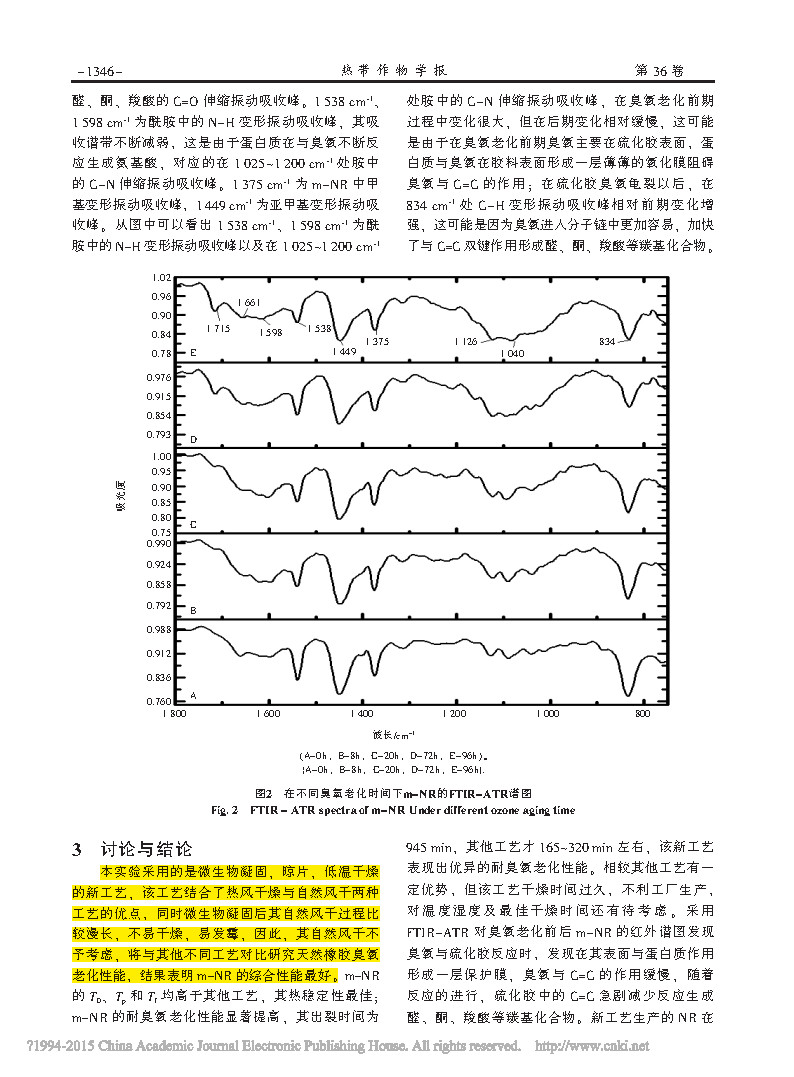

The solidification and drying of latex is an important part of natural rubber production. The physical and chemical properties of natural rubber (NR) and the physical and mechanical properties before and after ozone aging were studied under different solidification modes (acid solidification, microwave solidification, natural solidification, microbial solidification), different drying methods (natural air drying, hot air drying). It was found that the microbial coagulum had the highest tensile strength and the lowest rate of change under the same ozone aging conditions. The results of ozone aging study showed that the microbial solidification gel (m-NR) vulcanizate cracked the ozone for 16 h under static tension. Thermogravimetric analysis explored the thermal aging process of NR vulcanizates in different processes, and the aging effect of ozone on microbial coagulating gel was preliminarily investigated by attenuated total reflection Fourier transform infrared spectroscopy (FTIR-ATR).

Fig.1/3↑

Fig.2/3↑

Fig.3/3↑

The experiment adopts a new process of microbial solidification, drying and low-temperature drying. The process combines the advantages of hot air drying and natural air drying. At the same time, the natural air drying process of microorganisms after solidification is relatively long, difficult to dry and prone to mold. The natural air drying is not considered, and the natural rubber ozone aging performance will be compared with other different processes. The results show that the comprehensive performance of m-NR is the best.

Preparation of microwave solidified natural rubber (w-NR): Take a certain amount of fresh natural latex, adjust it to 25% dry glue content, take about 200 mL of latex and beaker, add 25% ammonium acetate latex, completely Dissolve evenly, put into XHMC-1 type microwave synthesis reactor (referred to as microwave instrument, produced by Beijing Xiangyu Technology Development Co., Ltd.), adjust the temperature and power. After 10 minutes, the latex is completely solidified, taken out, compressed, rinsed. The wet film is divided into two parts, and a part is dried by hot air at 70 °C for 7~12 h until the film is completely transparent, and the raw film w-NR-r is obtained, and the other part is naturally air-dried for 7 to 12 days to obtain a green film w- NR-z.