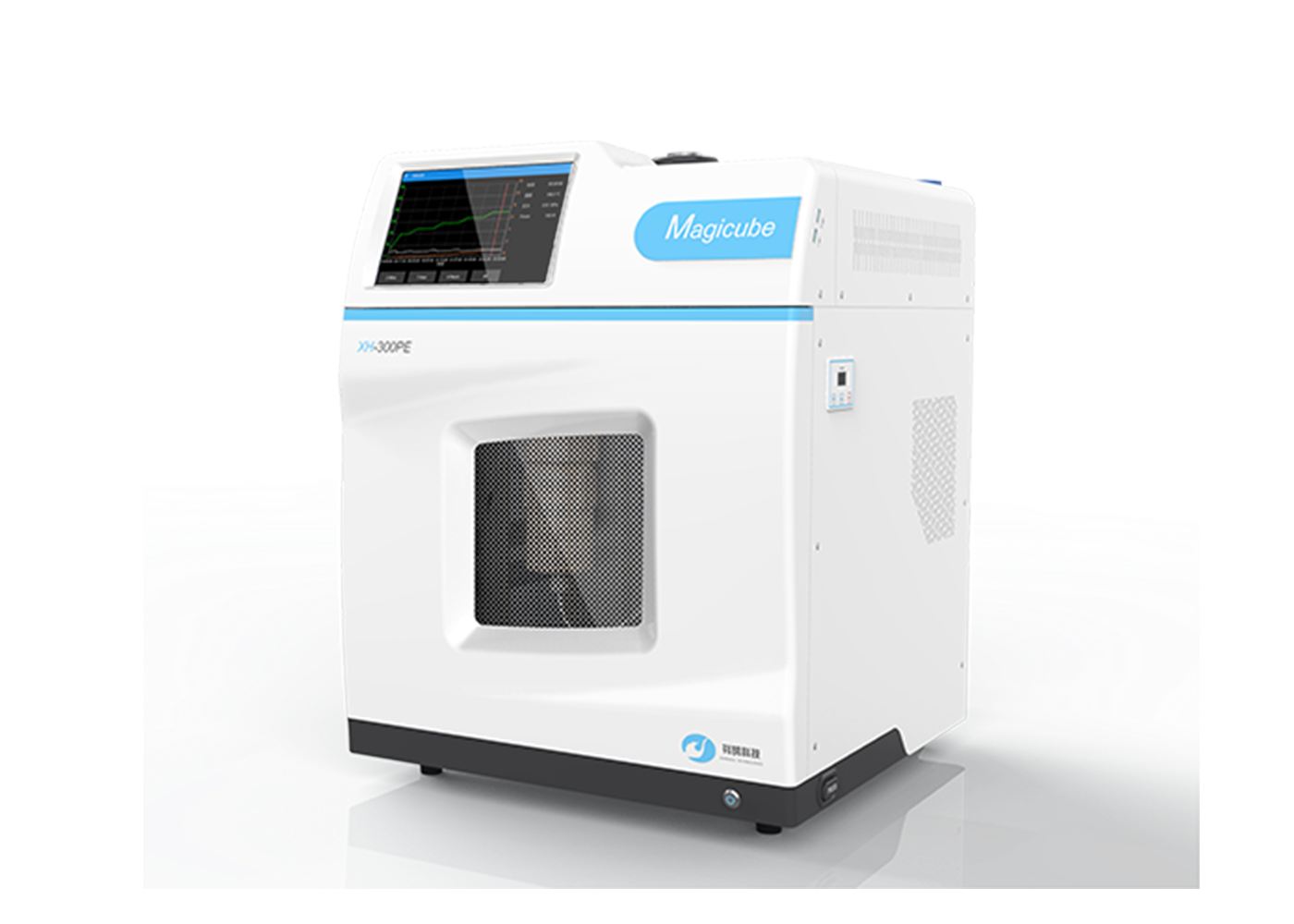

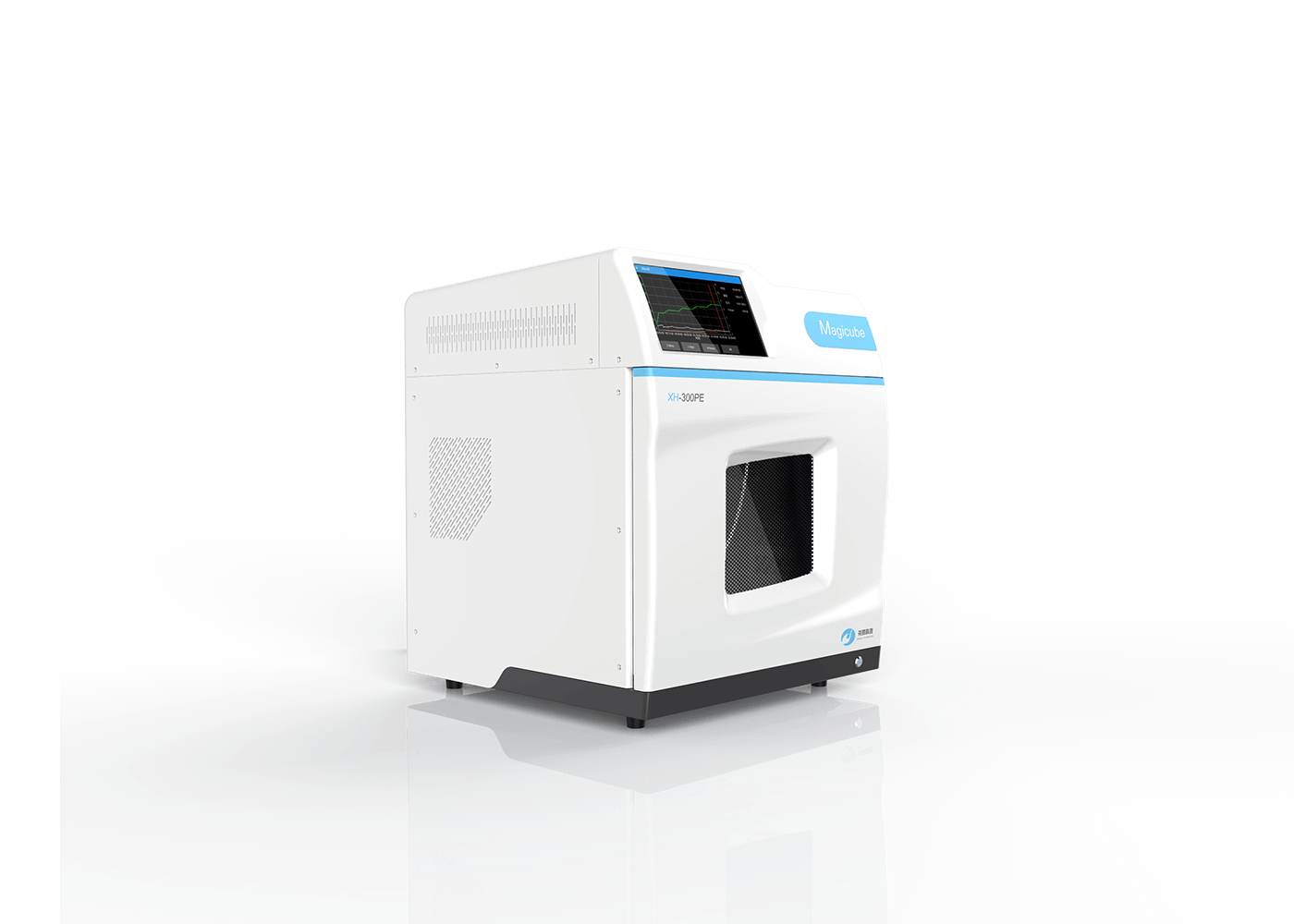

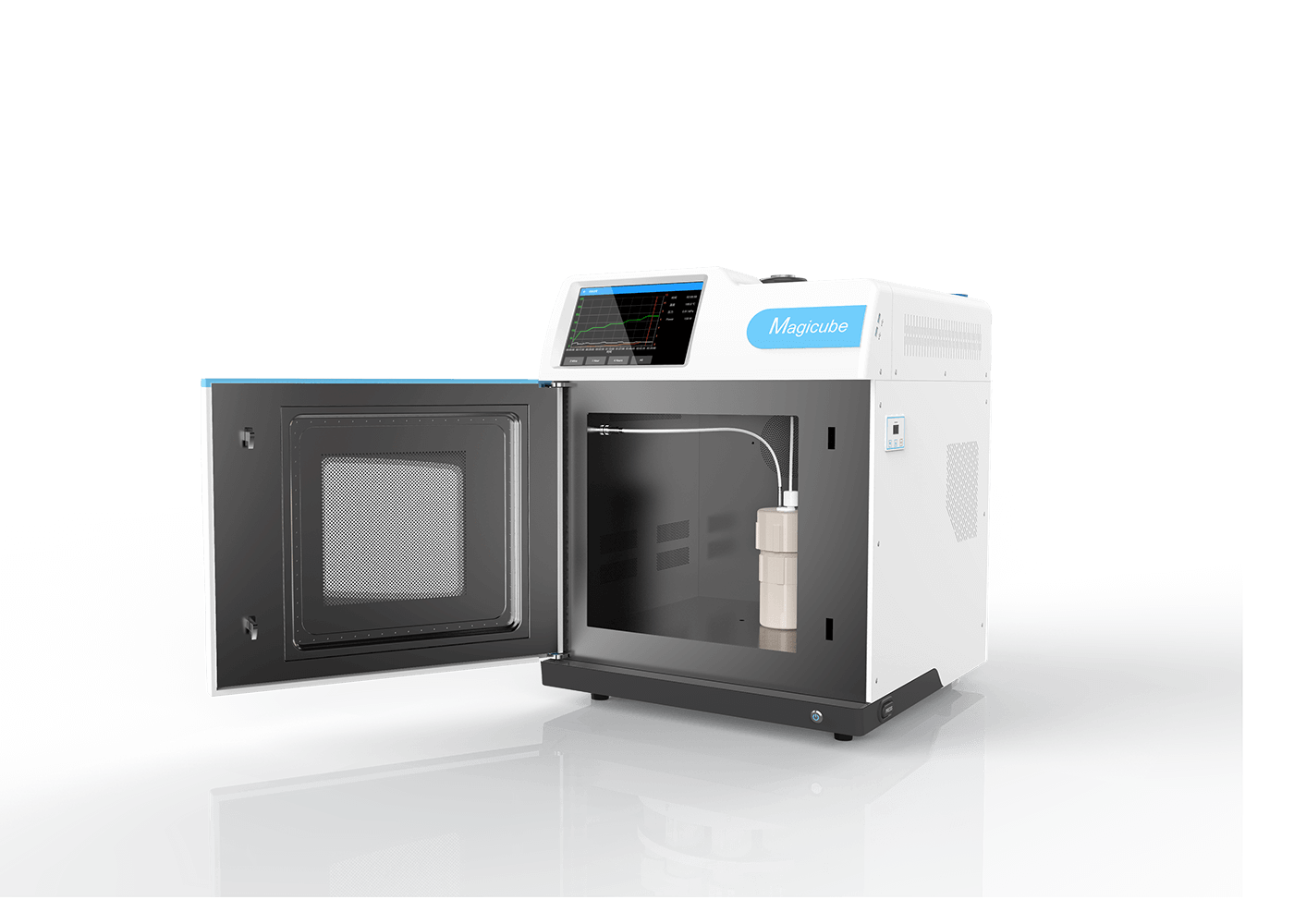

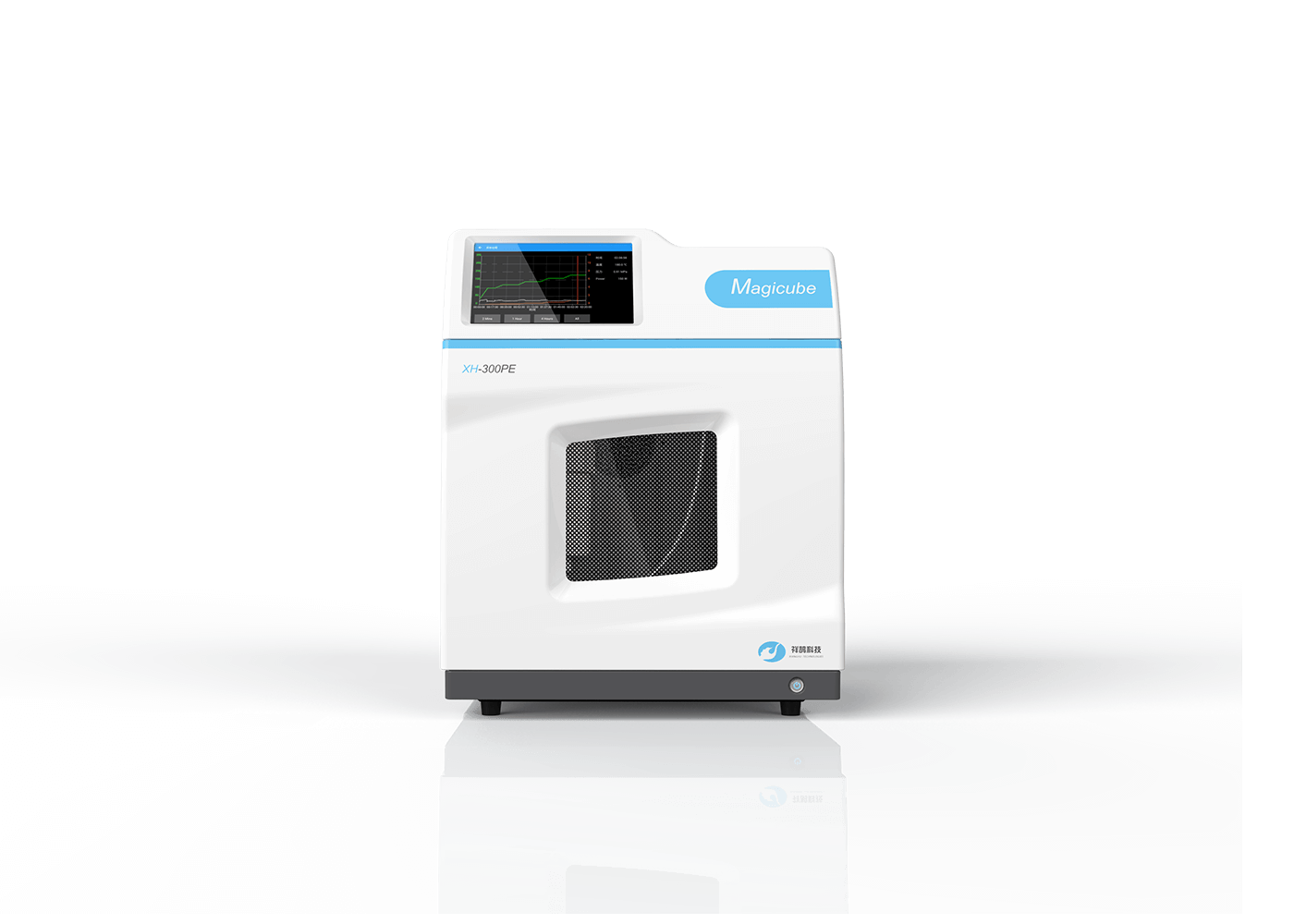

XH-300PE High Pressure Ultrasonic MW Combined Workstation

Magicube

Instrument functions:

High temperature microwave|High Pressure Microwave|Atmospheric microwave|liquid phase (chemistry)|Hydrothermal

Experimental function:

Experimental condition:

Experimental purpose: