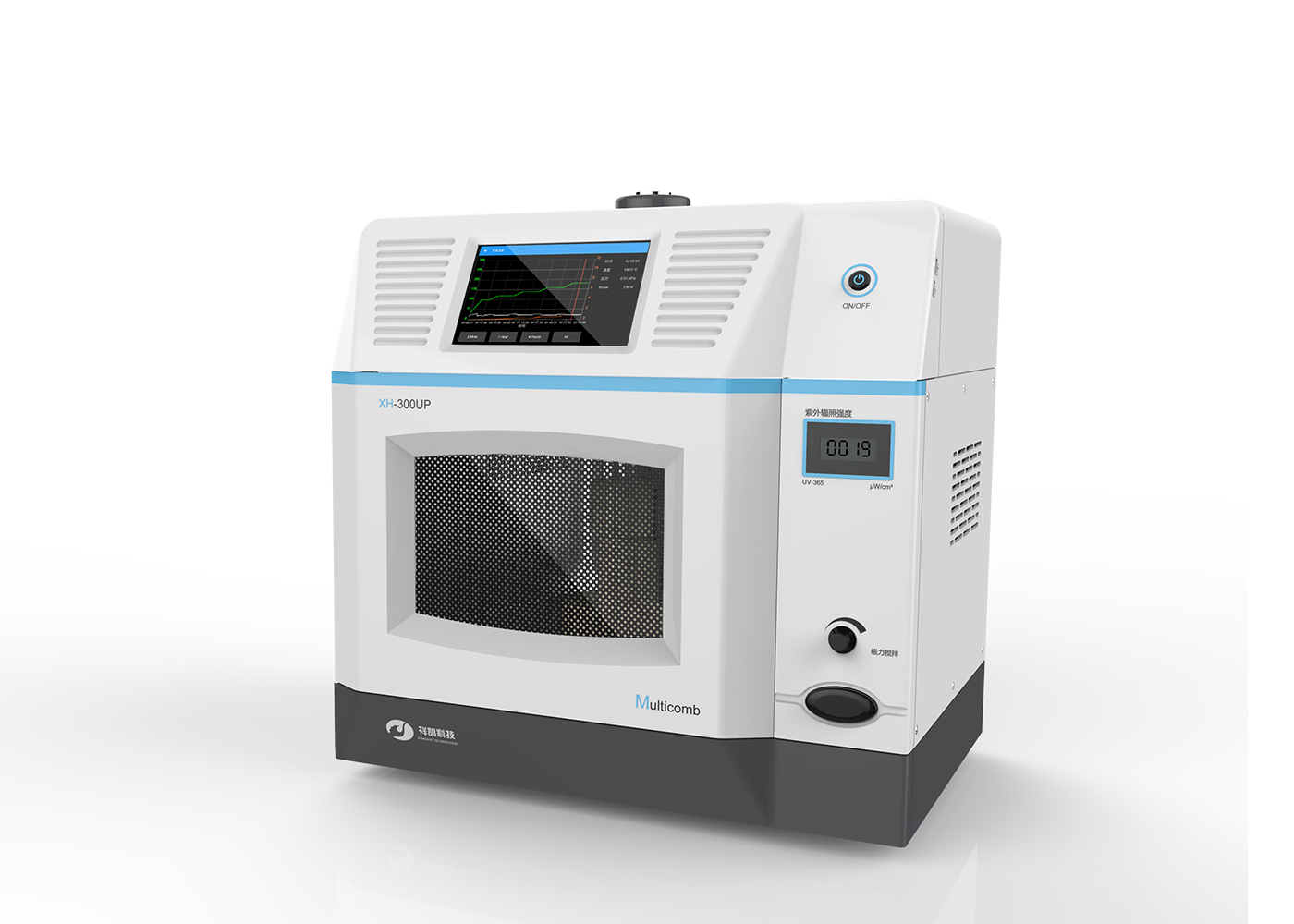

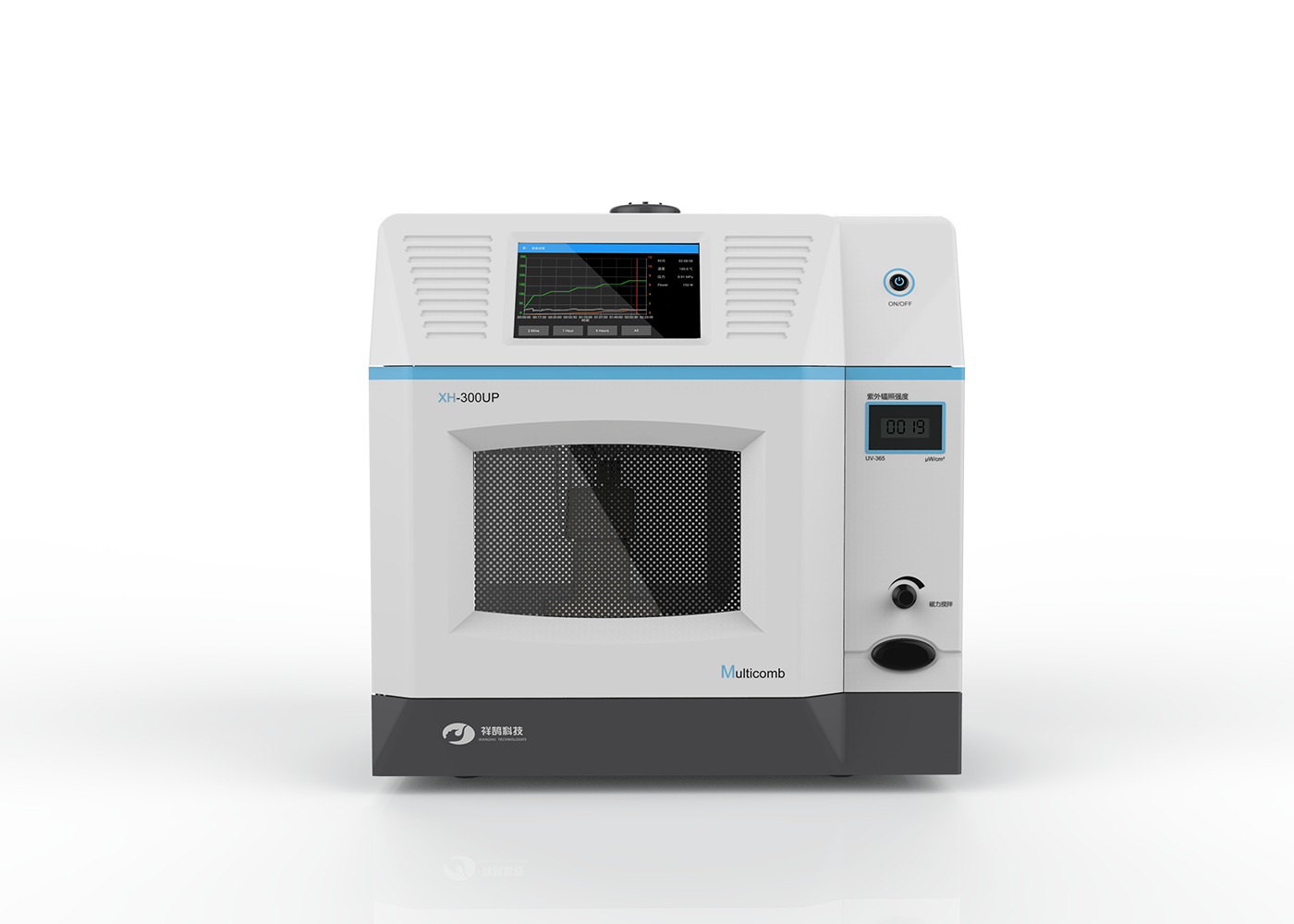

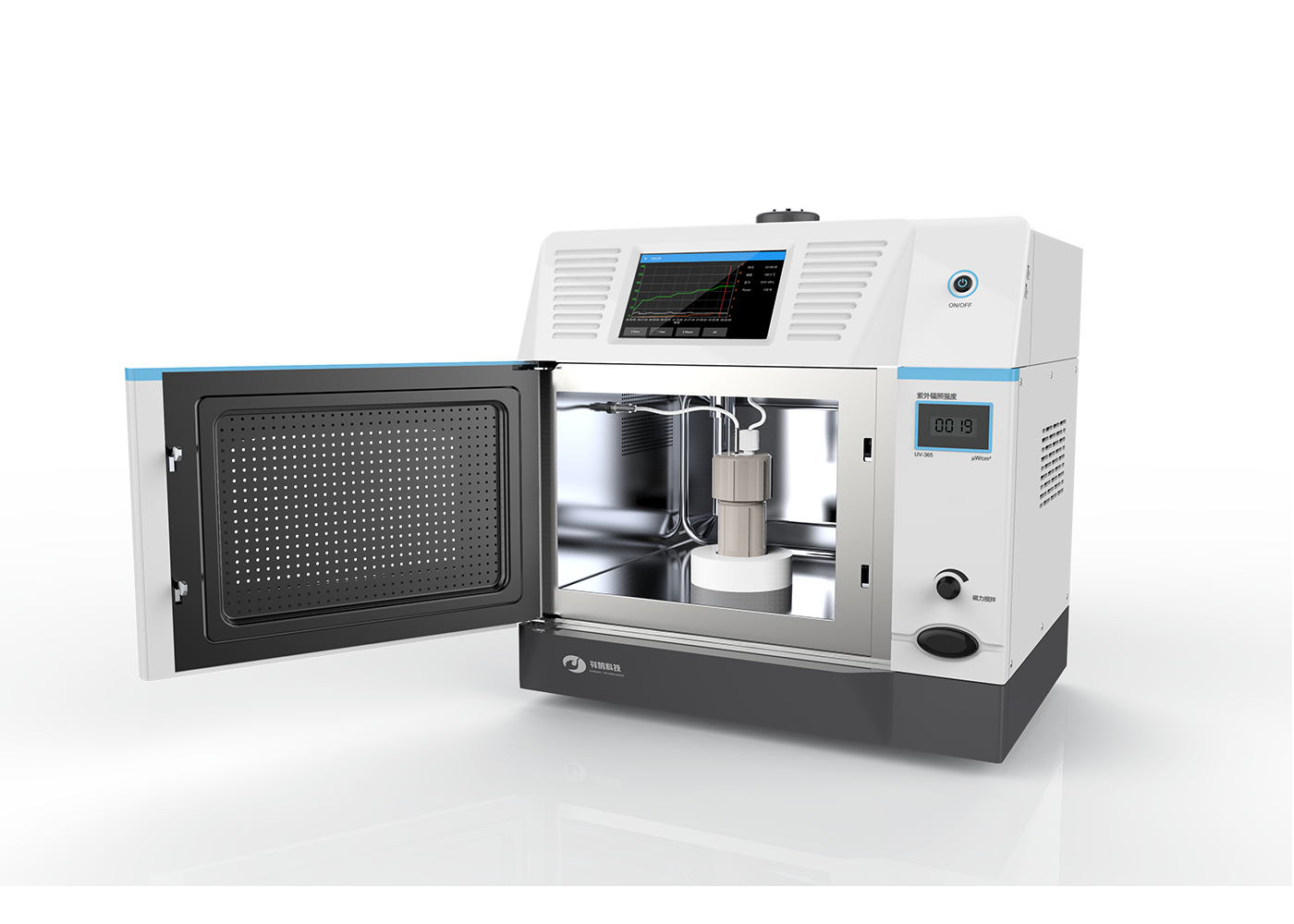

XH-300UP MW Ultrasonic Ultraviolet Combined Catalytic Synthesizer

Multicomb

Instrument functions:

Enyironmental waste deqradation |Organic/Drug Synthesis|Material Preparation |Natural Products Extraction|High Pressure Microwave|Atmospheric microwave|High temperature microwave|liquid phase (chemistry)|Hydrothermal

Experimental function:

Microwave Ultrasonic Ultraviolet Synergy|Microwave Ultrasonic Synergy|Photocatalysis|Ultrasound (scan)|Microwave

Experimental condition:

atmospheric|high temperature|liquid-phase (chemistry)

Experimental purpose:

Microwave Catalysis / Synthesis / Extraction|microwave hydrothermal|Ultrasonic extraction|photocatalysis