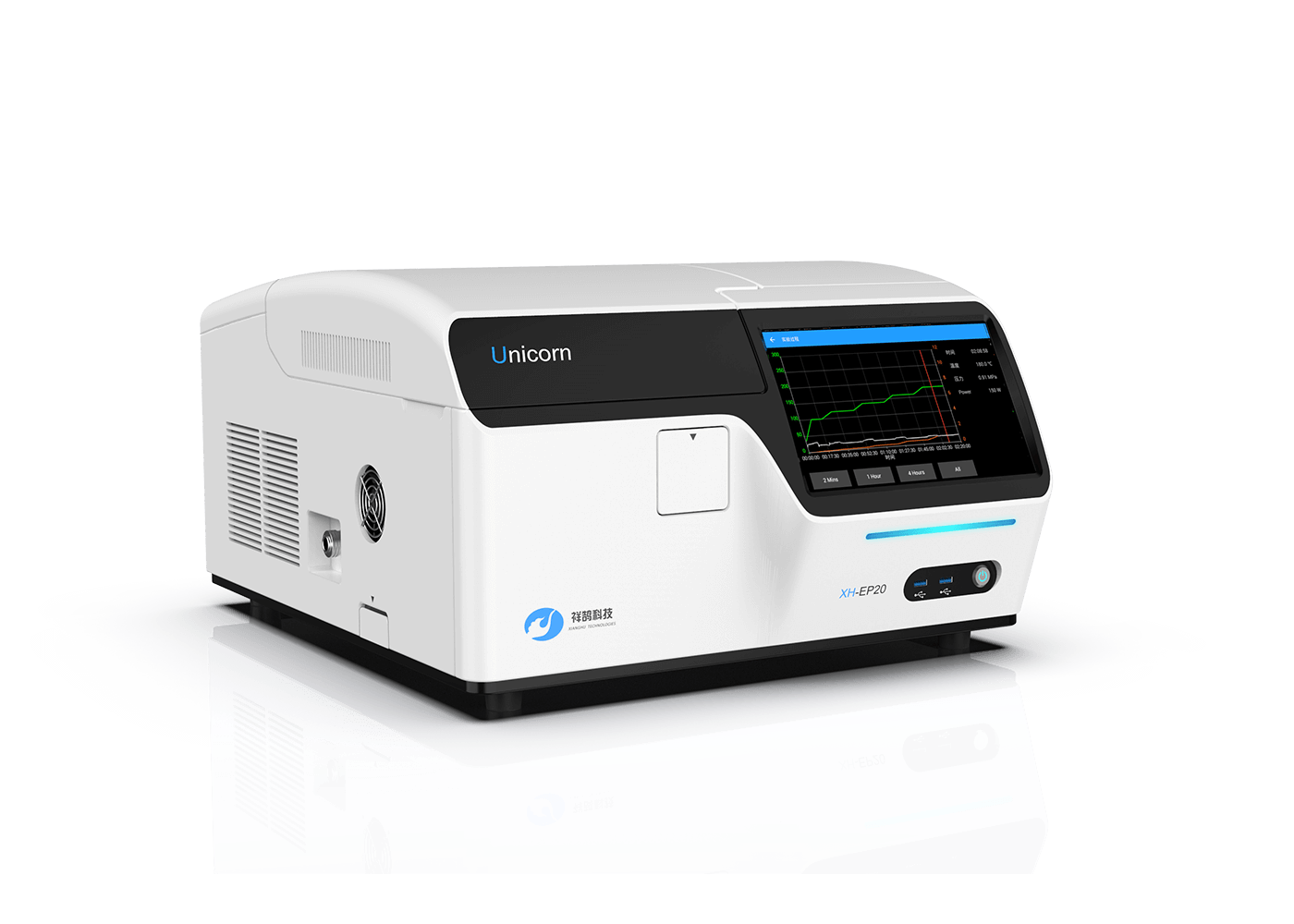

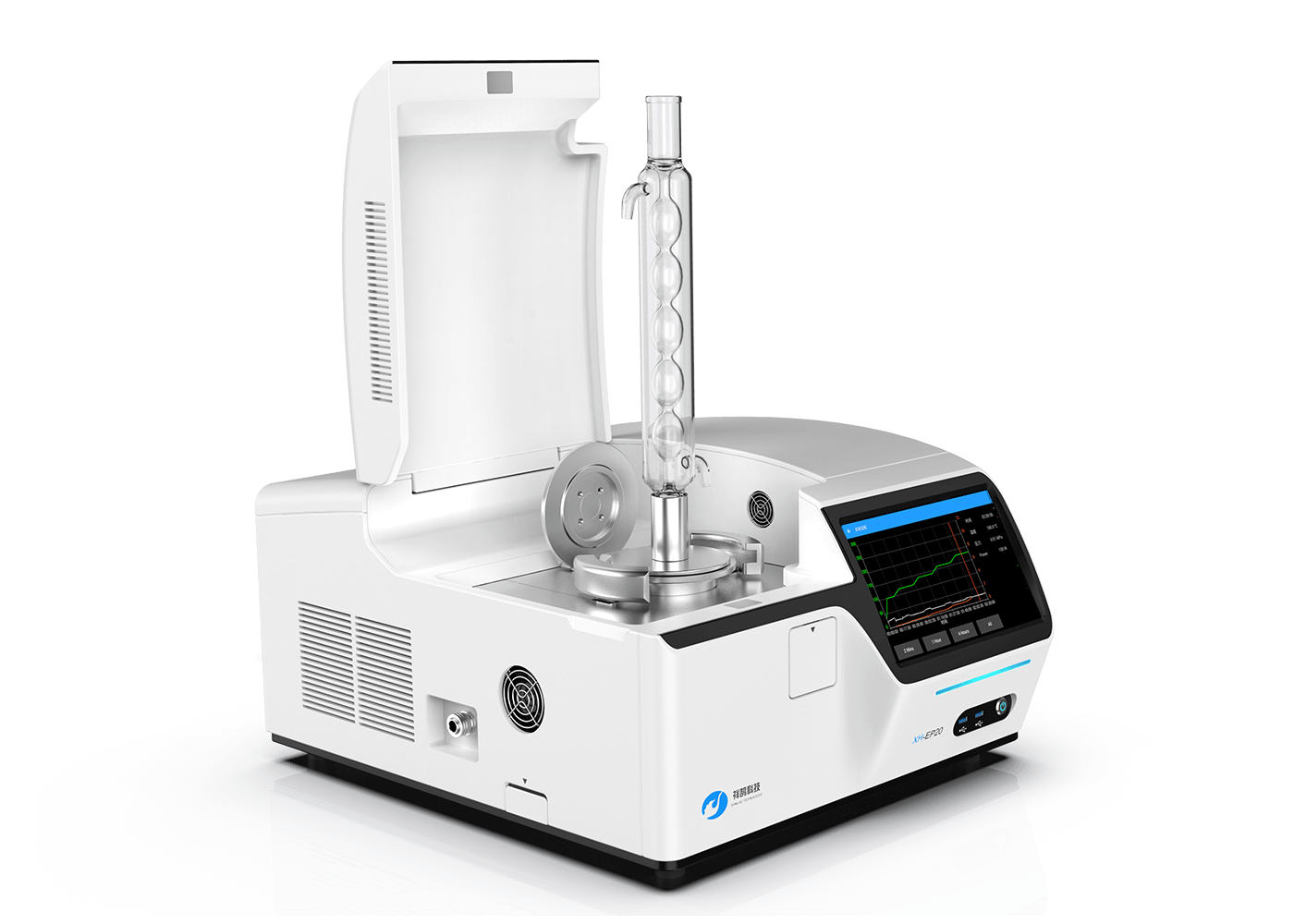

XH-EP20 Single-mode microwave synthesizer

Unicorn

Instrument functions:

High temperature microwave|High Pressure Microwave|Atmospheric microwave|liquid phase (chemistry)

Experimental function:

Experimental condition:

Experimental purpose: